Unbelievable Tips About What Is Roughness And Smoothness How To Make Standard Deviation Graph

Bendtsen roughness is achieved by clamping the test piece between a flat glass plate and a circular metal head and measuring the rate of airflow in ml/minute between the paper and head.

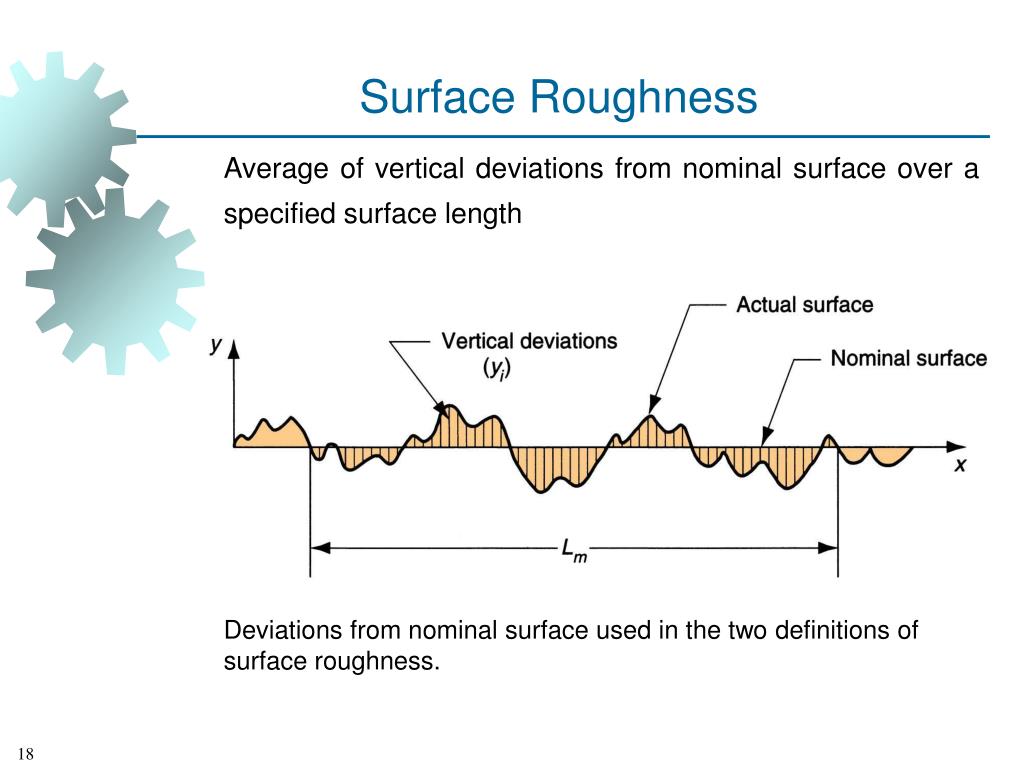

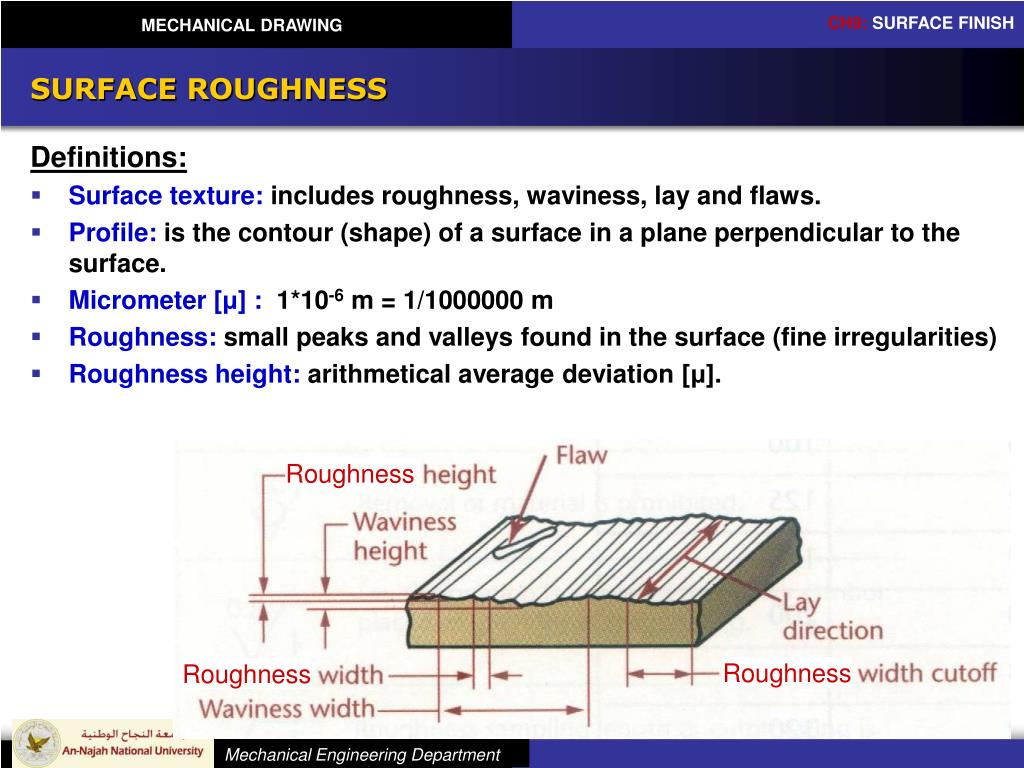

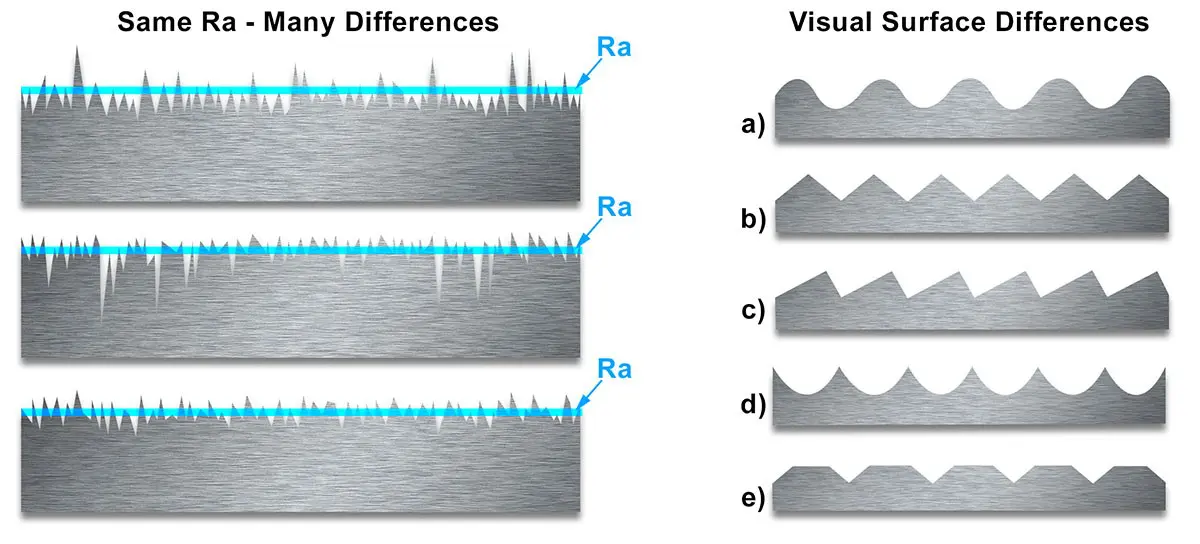

What is roughness and smoothness. To be completely smooth, you would use a smooth value of 1.0 or a rough value of 0.0. The ra surface finish chart shows the arithmetic average of surface heights measured across a surface. Surface roughness, frequently shortened to roughness, refers to small irregularities in surface geometry.

A comparison of low, medium and high values for smoothness (top to bottom). The roughness of the road made me wonder if my car would fall apart. Diamonds are used in various industries due to their excellent performance, but the roughness of synthetic diamonds remains a challenge.

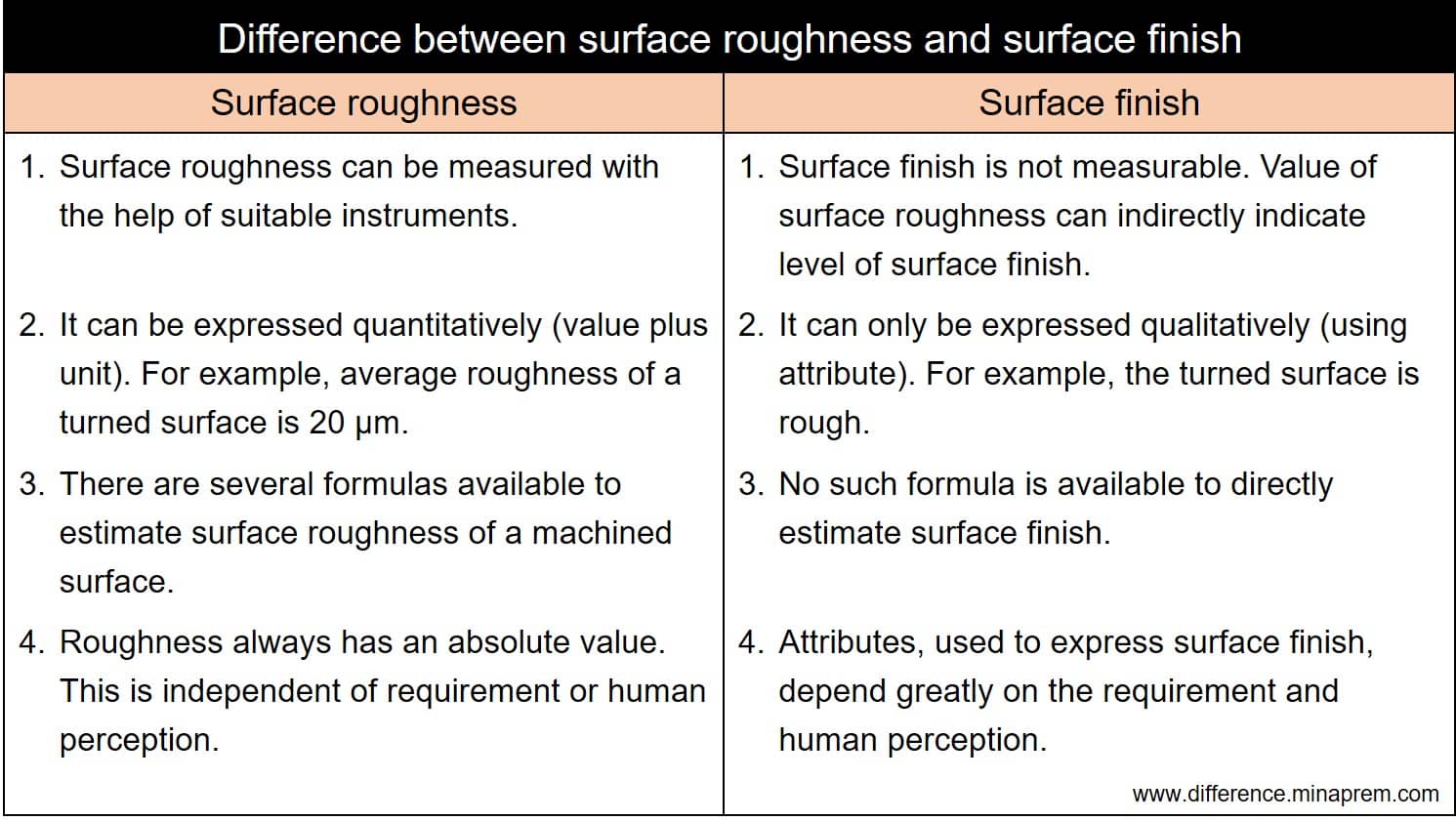

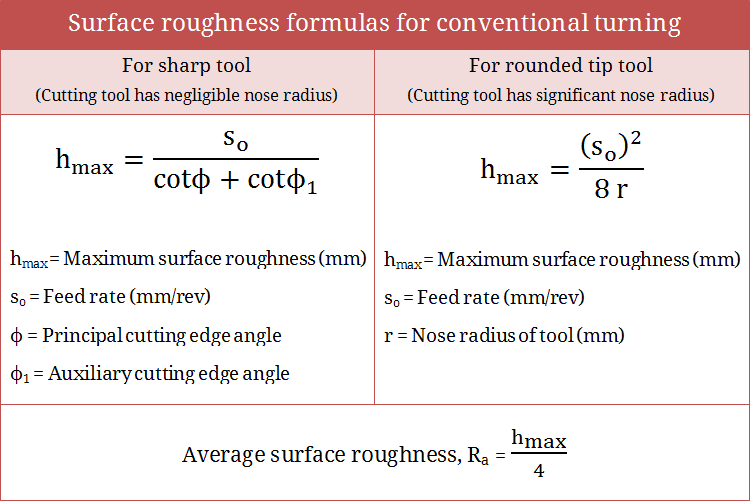

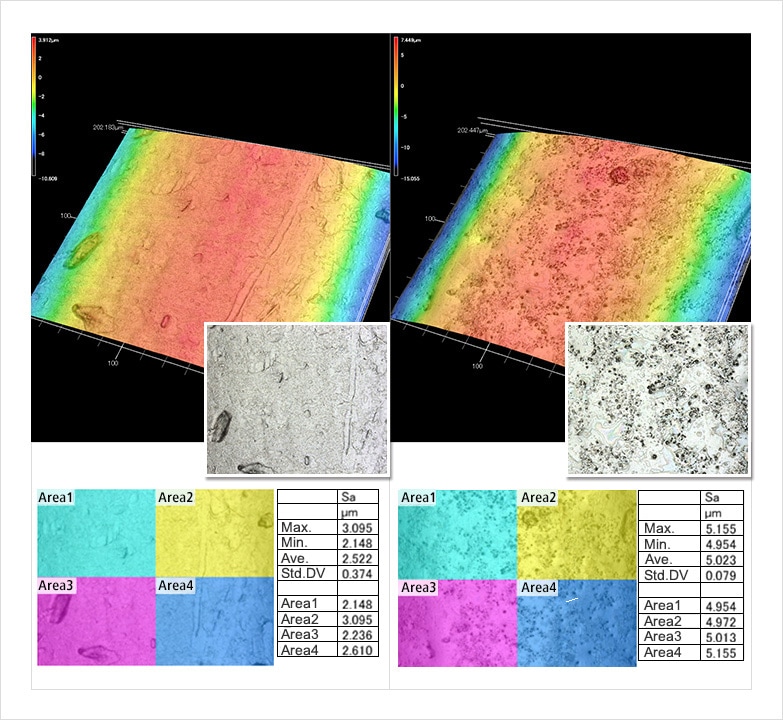

Surface roughness, also known as roughness, is a critical aspect of surface finish that is commonly specified, measured, and calculated. In tribology, rough surfaces wear faster and have. Surface profilometry based on either a diamond tip or laser beam has also long been used in the laboratory.

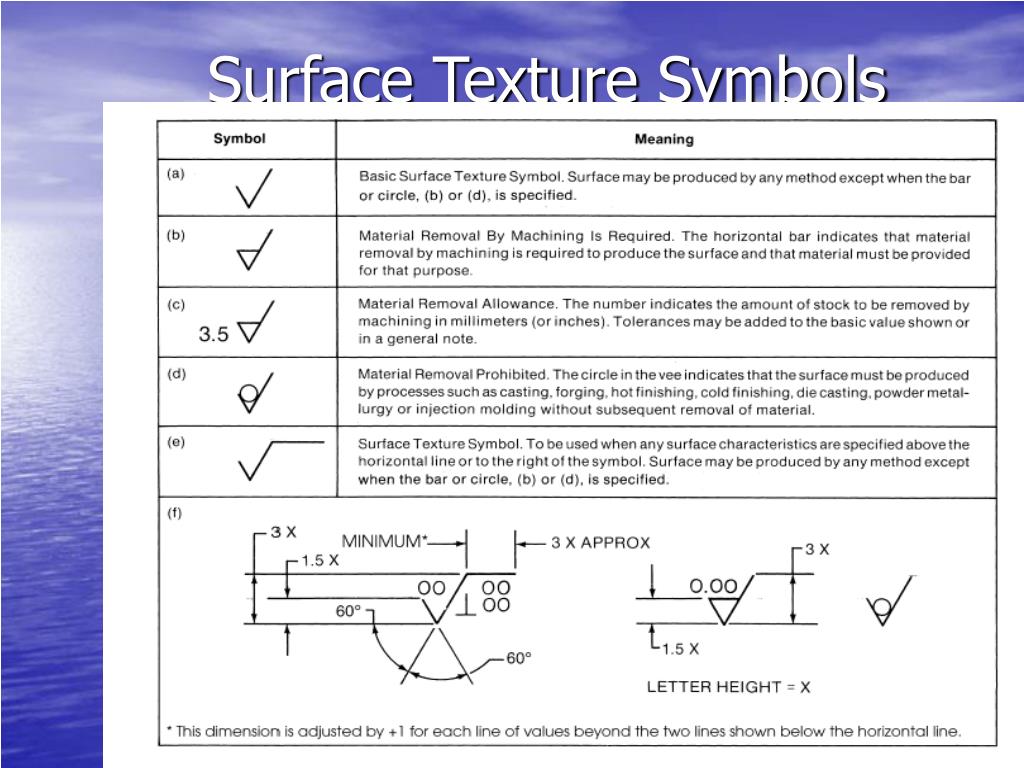

This article proposes a composite process for polishing chemical vapor deposition diamonds. Lay refers to the predominant or primary direction of the surface texture pattern on a material or object. The condition of being smooth.

The property of being rough, coarseness. So, factors that affect this decision boundary were identified through experiments. If these deviations are large, the surface is rough;

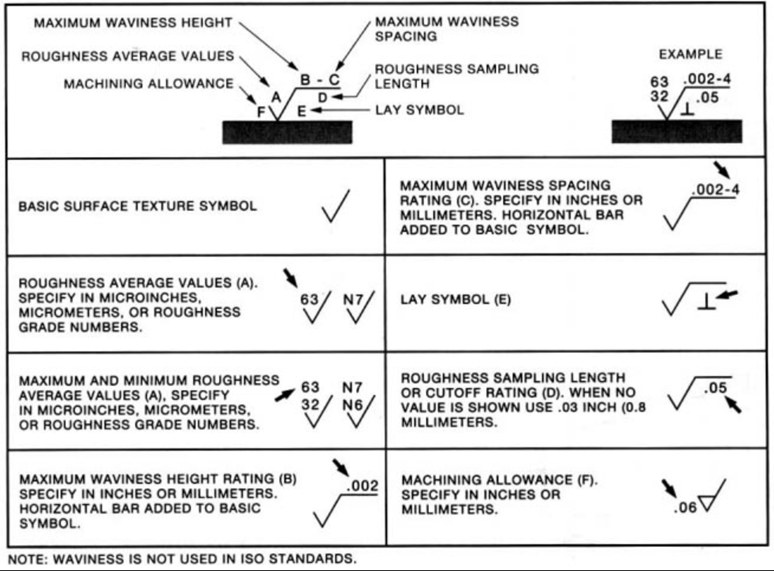

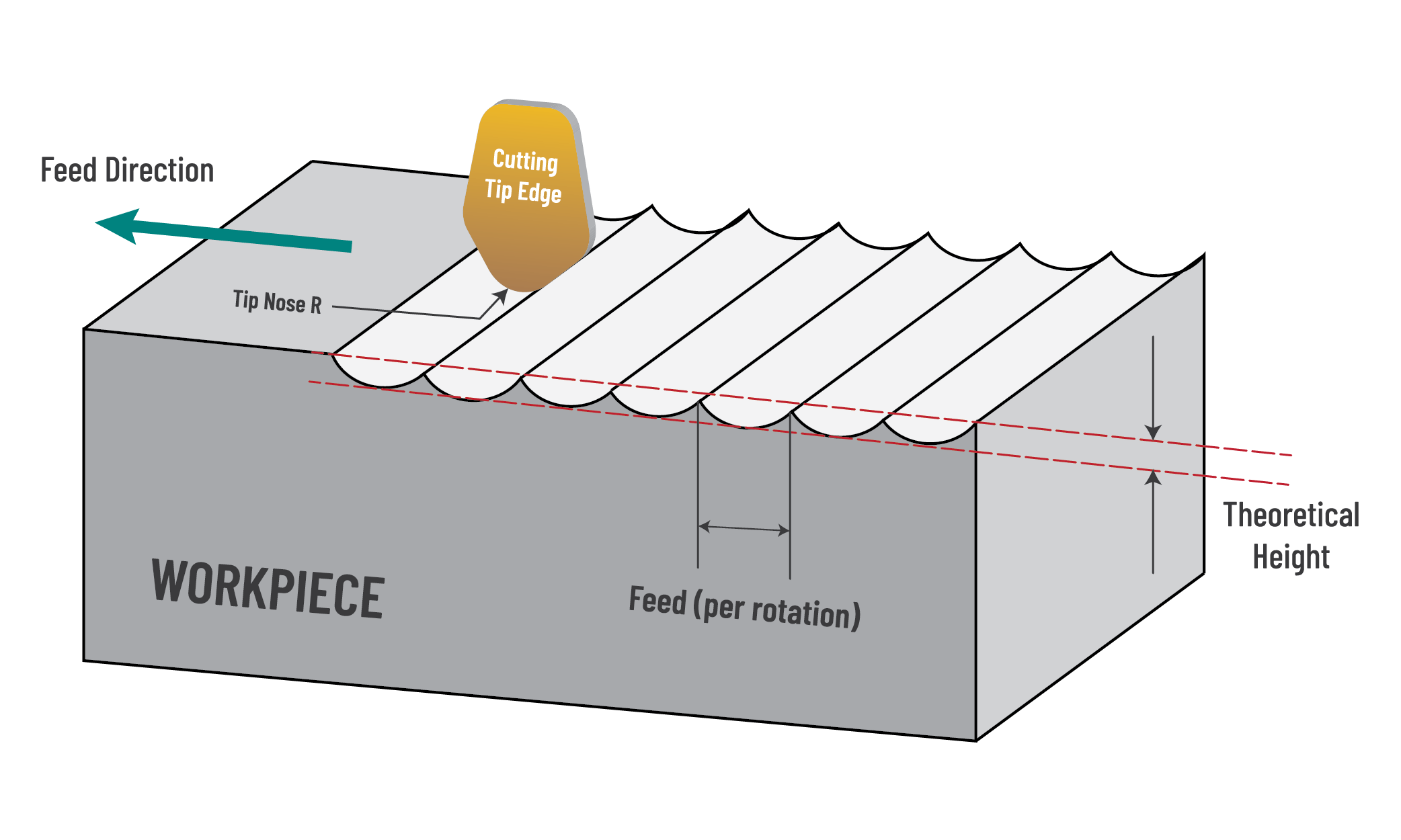

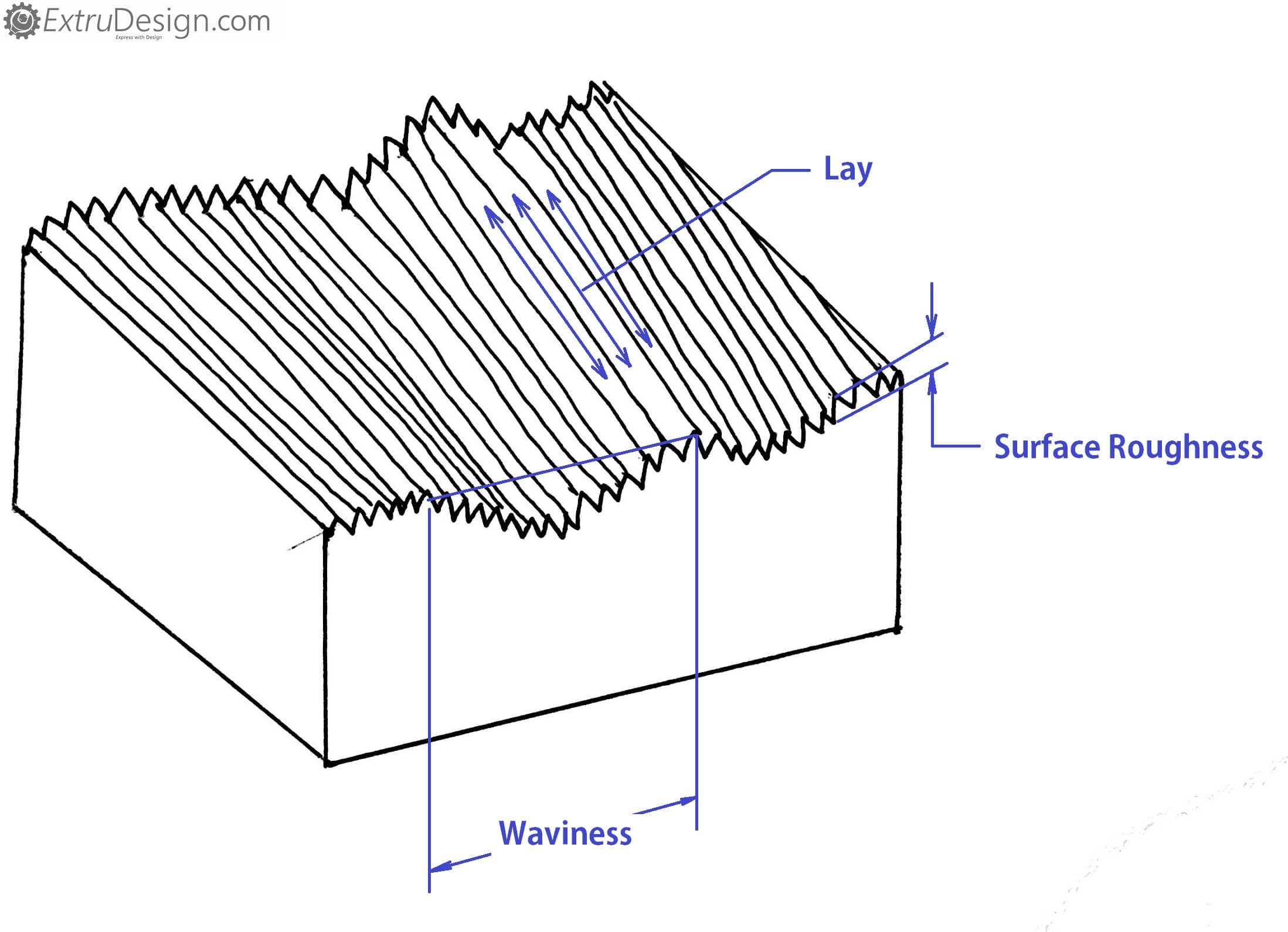

And what about the waviness? Surface roughness measures the closely spaced irregularities or variations, such as cutting tool marks and grinding wheel grit marks in the surface texture. An object will travel farther on a surface if it has less friction.

The most common method of testing smoothness or roughness in the paper and board sector is by one of three air leakage methods. It is defined by the variations in the direction of the normal vector of an actual surface compared to its ideal form.

Surface roughness is a measure of how rough or smooth the surface of a material is. Surface roughness is an excellent predictor of mechanical part performance because irregularities on the surface can produce nucleation sites for fractures or corrosion. Surface roughness is the measurement of the relative smoothness of a surface’s profile, calculated via the microscopic deviations in a surface's true form.

It is quantified by the deviations in the direction of the normal vector of a real surface from its ideal form. The lay can be described as the orientation of the surface features or texture, and it plays a crucial role in various. The overall level of roughness depends on the material and its manufacturing process.

Surface roughness is one component of describing how the shape of a surface deviates from its ideal form, where higher values correspond to rougher surfaces while lower values indicate the surface is smooth. If you have a smoothness map you can use the invert node to plug it into a roughness input. The larger the deviation from its true form, the rougher the surface, whilst the smaller the deviation, the smoother the surface.